Where to Buy Bath Towels in Bulk is one of the most common questions asked by B2B buyers across hospitality, retail, fitness, commercial laundry, healthcare, real estate, and private-label e-commerce sectors. Bath towels are among the most frequently purchased textile products in the business world—and unlike seasonal items, they require continuous replenishment, consistent quality, and reliable supply.

Why Bulk Bath Towels Matter in B2B Procurement

Bath towels play a foundational role in customer experience and operational efficiency. Hotels need towels that stay soft after hundreds of wash cycles. Gyms need fast-drying, durable options to withstand heavy use. Retailers and private-label brands require stylish, high-quality products that can differentiate them in competitive markets.

No matter the industry—hospitality in Germany, gym chains in the U.S., retail distributors in the UK, or property developers in Canada—the demand remains universal: a stable, scalable, and cost-effective source of high-quality towels.

The Challenge: More Than Just Finding a Supplier

Sourcing bath towels in bulk is not simply about locating the cheapest manufacturer. A successful procurement strategy must balance:

- Material quality and cotton type

- GSM and durability expectations

- Absorbency and softness

- Shipment method and landed cost

- Certifications (OEKO-TEX, REACH, etc.)

- Production capacity

- Supply stability and lead time

- Long-term reliability

This makes the sourcing process more complex—especially for buyers importing from manufacturing hubs like China.

What This Guide Will Help You Achieve

This comprehensive guide shows European and American B2B buyers how to make smarter, more profitable sourcing decisions by covering:

- The best places to buy bath towels in bulk

- Cost breakdowns and factory-direct pricing

- What to look for in a reliable supplier

- How to evaluate and audit factories

- How to avoid sourcing risks and hidden costs

- Logistics, shipping, and import essentials

- How to build long-term partnerships with manufacturers

Whether you’re purchasing for hotels, spas, gyms, retail shelves, or a private-label brand, this guide provides a clear roadmap to identifying the best suppliers, ensuring product consistency, and protecting your bottom line.

Understanding the Global Bulk Towel Market

Buying bath towels in bulk is not just a simple procurement task; it is a strategic supply chain decision. Every aspect — from raw cotton sources to weaving techniques, finishing processes, logistics, and customs regulations — influences the buyer’s final product cost, brand perception, durability, and customer satisfaction.

A High-Demand, High-Turnover Product

Bath towels need constant replenishment across nearly every service industry. Hotels lose towels to wear and tear, staining, laundering, and customer disappearance. Gyms experience heavy daily usage. Spas and salons require aesthetic consistency. E-commerce brands need high availability to satisfy Amazon Prime and Shopify lead times.

Average towel replacement cycle (B2B):

| Sector | Replacement Frequency | Drivers |

|---|---|---|

| Hotels | Every 3–6 months | High laundering intensity |

| Gyms & Fitness | Every 2–4 months | Sweat + heavy use |

| Spas & Wellness | Every 4–6 months | Appearance-sensitive |

| Retail/E-commerce | Ongoing | Inventory turnover |

| Commercial Laundries | Every 2–3 months | Chemical exposure |

Put simply:

Where there is frequent turnover, there is frequent B2B purchasing.

Key Regions Dominating Global Towel Production

Although some towels are produced domestically in the U.S. and Europe, the majority of the world’s volume comes from:

| Country/Region | Strengths | Approx. Global Share |

|---|---|---|

| China | Industrial scale, competitive cost, mature supply chain, customization | ~40–45% |

| India | Cotton source, specialized weaving | ~20–25% |

| Pakistan | Competitive pricing | ~10–12% |

| Turkey | High-quality cotton | ~8–10% |

| U.S. & Europe | Small-scale, niche luxury | <5% |

European and American B2B buyers frequently choose Chinese manufacturers because of their:

- Large capacity

- Fast sample development

- High customization capability

- Attractive pricing

- Consistent export experience

- Stable quality control practices

This guide will explore these advantages in detail.

Where to Buy Bath Towels in Bulk — All Sourcing Options Explained

When buying towels in bulk, businesses in the U.S. and Europe typically evaluate three sourcing channels:

- Domestic wholesalers

- International trading companies

- Direct partnerships with overseas manufacturers

(especially China, which supplies the majority of textiles globally)

Each option has its benefits and limitations depending on the buyer’s price tolerance, quality expectations, order size, branding needs, and long-term procurement strategy.

Option 1 — Buying from Domestic Wholesalers

Domestic wholesale suppliers provide convenience and reliability, which is why many businesses start here when sourcing towels.

Advantages

- Faster delivery

- No customs risk

- Easier communication

- Easy returns and customer support

- Familiar regulatory environment

Disadvantages

- Higher prices (30–70% more than factory-direct imports)

- Limited customization

- Smaller product variety

- Inventory may fluctuate

- Branding options minimal or expensive

When This Option Makes Sense

- You need immediate replenishment

- You’re purchasing smaller volumes

- You prefer lower risk and faster turnaround

- You do not need custom branding

But for most medium and large B2B buyers, overseas manufacturing becomes more appealing due to significant cost savings.

Option 2 — Buying from International Trading Companies

Many businesses source towels from trading companies instead of manufacturers.

Advantages

- Trading companies handle sourcing complexity

- Lower MOQs than factories

- Better communication (especially with export-focused firms)

- Risk management on behalf of buyer

Disadvantages

- Higher cost than buying factory-direct

- Limited control over production processes

- Inconsistent transparency about manufacturing source

Trading companies are useful for small-volume buyers who want the benefits of importing without the challenges.

Option 3 — Buying Directly from Overseas Manufacturers

This is where the biggest cost savings and highest customization possibilities exist.

Advantages

- Factory-direct pricing

- Unlimited customization

- Full control of GSM, materials, size, branding

- Consistent supply and large volume capabilities

- Manufacturers like BCHtowel provide complete OEM/ODM services

- Better suited for long-term growth

Disadvantages

- Longer delivery time

- Requires import knowledge

- Communication must be efficient

- Sample lead time precedes production

Ideal For

- Growing e-commerce brands

- Hotels, gyms, spas ordering thousands of units

- Retailers needing private-label towels

- Distributors and wholesalers

- International brands demanding cost control

Why Chinese Manufacturers Lead the Global Market

Why Chinese Manufacturers Lead the Global Market

The global textile industry has undergone several transformations over the past 30 years. From rapid modernization in the 1990s to post-pandemic supply chain restructuring in 2020–2023, one trend remains remarkably stable: China continues to lead the world in textile manufacturing — and bath towels are no exception. For European and American B2B buyers searching for bulk bath towels, China’s dominance is not a coincidence but the result of a deeply integrated ecosystem that combines raw material access, industrial scale, cost efficiency, and export experience.

This section explores why China remains the most reliable and cost-effective sourcing destination for bulk towel buyers and how its manufacturing infrastructure gives brands, retailers, hotels, gyms, and e-commerce sellers an advantage.

The Industrial Ecosystem Behind China’s Towel Manufacturing Power

China’s advantage is not only low labor cost — that is a small part of a much larger system. The real strength comes from a vertically integrated supply chain, which reduces dependency on imported materials, minimizes delays, and ensures consistent quality across large volumes.

1. Massive cotton resource access

While China is not the cheapest cotton producer, it is one of the largest. China consistently ranks among the top three cotton-producing nations globally, alongside India and the U.S. This ensures:

- Stable material availability

- Reduced supply disruptions

- Less fluctuation in pricing

- Strong control over cotton grade consistency

2. Clusters of textile manufacturing hubs

China’s textile industry benefits from regional specialization:

| Region | Strengths | Relevance for Towels |

|---|---|---|

| Shandong (Gaomi, Binzhou) | Cotton spinning, heavy loom capacity | Ideal for bulk towel production |

| Jiangsu & Zhejiang | Dyeing, finishing, premium weaving | Suitable for custom colors & high-end towels |

| Guangdong | Export logistics, flexible production | Fast turnarounds & OEM solutions |

| Hebei | Budget-focused textile lines | Suitable for lower-cost towels |

Unlike India or Pakistan, where capabilities are unevenly distributed, China’s tightly concentrated industrial zones allow manufacturers to perform:

- Spinning

- Weaving

- Dyeing

- Cutting

- Stitching

- Embroidery

- Packaging

…all within the same regional ecosystem.

This eliminates delays and significantly increases production consistency.

3. Industry experience built over 30+ years

China is not a “new” player in towel manufacturing. Many factories have been exporting for decades, building:

- Mature quality control systems

- Familiarity with EU/US testing standards

- Long-term partnerships with distributors

- Ability to handle complex orders

- Professional communication processes

Factories like BCHtowel, for example, benefit from this historical foundation. Their operations are structured specifically for B2B buyers in Europe and America, allowing them to provide stable quality, consistent GSM accuracy, and reliable colorfastness.

Cost Advantages — Not Just Low Labor Cost

Many buyers assume China is competitive simply due to lower labor cost, but the real cost advantage comes from:

1. Material efficiency

Chinese factories purchase cotton in extremely large volumes. This gives them:

- Better raw material pricing

- Lower cost per bale

- Stronger control over fiber quality standards

2. Optimization across production

China has efficiency advantages across the entire value chain:

- Automated air-jet looms

- High-density weaving technology

- Efficient dyeing processes

- Energy-saving finishing systems

- Low defect rates

These efficiencies collectively reduce the cost of production, not just labor.

3. Economies of scale

Factories producing 50,000–200,000+ towels per day (not uncommon in China) create economies that are impossible for U.S. or EU suppliers to match.

4. Competitive logistics

China’s shipping infrastructure is among the most advanced in the world:

- Major ports: Qingdao, Ningbo, Shanghai, Shenzhen, Guangzhou

- Extensive rail lines

- High freight frequency to EU/US

Many manufacturers have long-term relationships with freight forwarders, which allows them to:

- Secure better shipping rates

- Provide more predictable delivery timelines

- Offer door-to-door services for B2B buyers

Customization Capabilities Unmatched by Domestic Suppliers

Most domestic wholesalers in Europe or the U.S. stock standardized towels. This means fixed colors, GSM, patterns, and sizes. For B2B buyers seeking branding, private-label towels, or customized colors, domestic suppliers rarely meet requirements.

Chinese manufacturers, in contrast, provide full customization:

What buyers can customize:

| Customization Type | Description | Common Use Cases |

|---|---|---|

| GSM (Weight) | 350–800 GSM | Hotels, gyms, spas, retail |

| Material | 100% cotton, combed cotton, ringspun, bamboo blends, recycled cotton | Sustainability-focused markets |

| Size | Bath towel, bath sheet, hand towel, face towel | Full towel sets |

| Color | Pantone-matched dyeing | Hospitality branding |

| Weave Type | Terry, zero twist, waffle, jacquard | Retail/e-commerce |

| Logo | Embroidery, jacquard, printing | Private labels |

| Packaging | OPP bag, gift box, belly band | Retail & e-commerce |

This level of customization — especially at competitive pricing — is a major reason international buyers choose China.

B2B-oriented factories like BCHtowel specialize in these OEM/ODM services, making them valuable partners for global buyers needing consistent branding.

Credible Quality Standards for EU & US Markets

European and American markets have strict textile regulations. Chinese manufacturers exporting towel products regularly comply with:

- OEKO-TEX Standard 100

- ISO 9001 Quality Management

- Colorfastness Standards (ISO 105)

- AZO-free dyes

- REACH compliance

- Product durability testing

Factories exporting for 10–20+ years understand the quality expectations of:

- Hotels in Germany

- Gyms in France

- Retail chains in the UK

- E-commerce brands in the U.S.

- Department stores in Canada

The result: towels designed specifically to withstand high washing temperatures, chlorine exposure, and heavy commercial use.

Advanced Technology and Production Methods

Chinese towel factories are widely equipped with modern technology. The most common include:

1. Air-Jet Looms

- Faster weaving speed

- Higher weaving uniformity

- Lower defect rate

- Better density control

2. Auto-Dyeing Systems

- Pantone color precision

- Low color variation

- Energy efficiency

3. Automated Cutting and Hemming Lines

- Precise sizing

- Consistent edge stitching

- Faster production speed

4. Computerized Embroidery Machines

- High-detail logo embroidery

- Consistent thread tension

- Fast changeovers

5. Optical Inspection Systems

- Automated detection of weaving defects

- Consistent quality for large volume orders

Manufacturers like BCHtowel apply these technologies to ensure consistent quality across tens of thousands of units, which is essential for hotels, spas, and retail brands.

Flexible MOQ Options for Different Buyer Types

One of the major advantages of sourcing from China is MOQ (Minimum Order Quantity) flexibility. While many domestic suppliers require buyers to accept whatever stock is available, overseas manufacturers, especially Chinese ones, offer more tailored solutions.

Typical MOQs in China:

| Order Type | MOQ Range | Ideal For |

|---|---|---|

| Standard In-Stock Towels | 100–500 units | Small businesses / urgent orders |

| Custom Color Towels | 1,000–3,000 units | Retail brands, hotels |

| Jacquard / Woven Logo | 3,000–5,000 units | Premium retail |

| Full Private Label Set | 1,000–2,000 sets | E-commerce sellers |

| Bulk Hospitality Towels | 5,000–50,000 units | Hotels, resorts, gyms |

This allows buyers in Europe and America — including new brands — to launch private-label towel lines with manageable initial investment.

Strong Understanding of International Logistics

Chinese B2B manufacturers have extensive export logistics experience. This includes:

- FOB, CIF, DDP, and EXW shipping

- Sea freight and air freight options

- Door-to-door delivery to the U.S. and Europe

- Consolidation warehouses

- Assistance with customs clearance

Factories like BCHtowel also work with long-term freight partners who specialize in textile shipments, helping buyers reduce:

- Unexpected import costs

- Shipping delays

- Customs complications

Price–Value Balance Ideal for EU & US Buyers

Even though China is not always the cheapest global option, it consistently provides the best overall value when balancing:

- Quality

- Cost

- Production speed

- Customization

- Logistics

- Long-term supply stability

Factories like BCHtowel have optimized their structures around this price–value balance, making them strong candidates for businesses seeking scalable, reliable towel sourcing solutions.

Summary — Why China Remains the #1 Choice for Bulk Towel Buyers

To summarize the above sections, here is a simplified comparison:

| Sourcing Location | Quality | Customization | Price | Reliability | Production Speed | Best For |

|---|---|---|---|---|---|---|

| China | High | Excellent | Low–Medium | Very High | Fast | EU/US brands, hotels, retail |

| India | High | Medium | Medium | Medium | Moderate | Traditional-style towels |

| Pakistan | Medium | Medium | Low | Lower | Moderate | Price-sensitive buyers |

| Turkey | High | Low | High | High | Moderate | Luxury cotton |

| USA/EU | Very High | Low | Very High | High | Fast | Urgent needs |

China remains the global leader because it offers the most balanced combination of all factors, especially for:

- Large-volume orders

- Private-label development

- Retail expansion

- Wholesale distribution

- Global brand growth

Factories like BCHtowel represent this modern Chinese manufacturing model — professional, efficient, export-oriented, and capable of delivering tailored solutions for European and American buyers.

Where to Buy Bath Towels in Bulk

Bulk towel sourcing is not only about finding the lowest unit price — it requires understanding global supply networks, manufacturer capabilities, geographic advantages, logistics performance, and long-term scalability. For businesses in Europe and America, the bulk towel sourcing landscape can be divided into four major channels:

- Local wholesalers;

- International distributors;

- Online marketplaces;

- Direct collaboration with manufacturers (primarily in China and Turkey).

Each channel comes with distinct benefits and limitations. This section provides a professional-level comparison to help hospitality groups, retailers, laundries, and importers make informed purchasing decisions.

Local Wholesalers in Europe & America

Local wholesalers remain a popular choice for small and mid-sized businesses because they offer immediate supply and low-risk purchasing. These distributors generally stock common SKUs such as 400–600 GSM bath towels, economy-grade hotel towels, and basic white terry items intended for commercial laundries.

Pros of Local Wholesalers

- Faster restocking — ideal for urgent needs or seasonal peaks.

- No import duties — reduces administrative burden.

- Simpler communication — fewer language or time zone barriers.

- Ability to inspect products before purchase (for some retailers).

Cons of Local Wholesalers

- Higher prices due to domestic labor and warehousing costs.

- Limited customization options — custom GSM, embroidery, or packaging often unavailable.

- Smaller inventory variety, especially for higher-end or specialty towels.

- Less competitive for large-volume buyers, especially over 10,000 pieces.

Best for:

- Boutique hotels

- Independent gyms and spas

- Small retailers

- Businesses needing low-volume or emergency replenishment

International Distributors & Trading Companies

These companies import towels from manufacturing countries and resell them to Western markets. They act as intermediaries between factories and buyers.

Advantages

- Moderate pricing — usually lower than domestic wholesalers.

- Variety of SKUs — distributors source from multiple factories.

- Lower MOQs than direct factories.

- Familiar with EU/US quality standards.

Disadvantages

- Still more expensive than direct factory sourcing.

- Limited transparency — buyers may not know which factory produced the towels.

- Inconsistent product quality, since products may come from multiple sources.

Best for:

- Medium-sized hospitality groups

- Retailers requiring mid-volume orders

- Buyers needing reliable but not fully custom products

Online Marketplaces (Alibaba, Amazon Business, Global Sources, Made-in-China)

Online sourcing has expanded significantly in the last decade, allowing small buyers to connect with global factories.

Pros

- Large variety of suppliers and SKUs

- Lower entry barriers — low MOQs

- Easy price comparisons

- Suitable for test orders and sampling

Cons

- Mixed supplier reliability — agents, trading companies, and actual factories look similar.

- Inflated product photos and inconsistent specifications.

- Lack of professional consultation for B2B needs like GSM stability, shrinkage rates, or laundering durability.

- Risk of hidden costs, such as freight, taxes, or quality problems after arrival.

Best for:

- Startups exploring private labeling

- Small importers seeking low entry thresholds

- Businesses testing product styles or materials before committing to a long-term supplier

Direct Towel Manufacturers in China (Most Cost-Effective for B2B Buyers)

China remains the global center of towel production, accounting for a significant share of exports to Europe and America. The country’s manufacturing ecosystem offers strong advantages in vertical integration, efficiency, and scale.

Why China Dominates Bulk Towel Manufacturing

1. Fully Integrated Supply Chains

From cotton spinning, weaving, dyeing, finishing, cutting, to packaging — many Chinese manufacturers operate vertically integrated facilities, significantly reducing production cost and lead time.

2. Competitive Pricing for Large Orders

Factories in China benefit from economies of scale.

For orders above 5,000–10,000 pieces, China typically provides the best price-to-quality ratio compared to Turkey, India, or Pakistan.

3. Customization Capabilities

Chinese manufacturers excel in R&D and customization:

- GSM from 300 to 900

- Cotton options: combed, ring-spun, zero-twist, long-staple

- Weaves: terry, waffle, jacquard

- Embroidery: logo stitching, hotel branding

- Colors: reactive dye, vat dye, custom Pantone

- Packaging: PE bag, paper band, gift box, OEM retail packaging

4. Compliance with EU/US Standards

High-quality factories routinely support:

- OEKO-TEX® Standard 100

- ISO 9001 & 14001

- European REACH regulations

- U.S. CPSIA and flammability standards

- AZO-free and eco-safe dyeing

5. Stable Export Logistics

China has world-class export ports (Shanghai, Ningbo, Qingdao, Shenzhen).

Bulk orders benefit from:

- Competitive LCL/FCL shipping

- Predictable transit times

- Mature freight forwarding support

Best for:

- Large hotel chains

- Gym franchises

- Commercial laundries

- Retail chains

- Importers developing private-label towel brands

- Businesses needing long-term, scalable supply

Turkey, India, and Pakistan (Alternative Production Regions)

These regions also produce quality towels, each with unique strengths.

Turkey

- Famous for Turkish cotton (long-staple fibers)

- Higher price point but soft and luxurious

- Best for upscale spas and boutique hotels

India

- Strong in organic and handloom-style towels

- Larger variety of artisanal patterns

- Competitive mid-range pricing

Pakistan

- Known for budget-friendly bulk towels

- Strong exporter for hotel and cleaning industries

- Lower consistency compared to China/Turkey

When to Consider These Regions:

- Buyers seeking diversified supply chains

- Specialty cotton sourcing (e.g., Turkish Aegean cotton)

- Unique styles not widely available in China

Comparison Table: Where Should You Buy Bulk Bath Towels?

| Sourcing Channel | Price Level | MOQ | Customization | Lead Time | Best For | Weaknesses |

|---|---|---|---|---|---|---|

| Local Wholesalers (EU/US) | High | Low | Very limited | Immediate | Small hotels, gyms | High cost, limited choice |

| International Distributors | Medium-high | Medium | Limited | 1–3 weeks | Retailers, mid-size buyers | Not cost-optimal for large orders |

| Online Marketplaces | Medium | Low | Moderate | 2–6 weeks | Startups, sampling | Mixed reliability |

| China Manufacturers | Low | Medium-High | Excellent | 15–45 days | Large-volume buyers, OEM brands | Requires import process |

| Turkey Manufacturers | Medium-high | Medium | Good | 20–50 days | Luxury buyers | Higher pricing |

| India/Pakistan Manufacturers | Medium | Medium | Moderate | 20–50 days | Price-conscious buyers | Inconsistent quality control |

Why Most Western B2B Buyers Choose Chinese Manufacturers

Most European and American businesses ultimately choose direct sourcing from China because:

- 30–50% lower cost than domestic wholesalers

- More customization options

- Large-volume capacity for chain brands

- Stable and repeatable quality

- Advanced dyeing and weaving technology

- Professional export service

- Better packaging flexibility for retail

For businesses planning to grow, China remains the only sourcing destination capable of supporting unlimited scaling without compromising cost-efficiency.

Introducing BCHtowel: A Reliable Chinese Factory for EU & US Bulk Buyers

BCHtowel is a professional Chinese towel manufacturer specializing in B2B export for the European and American markets. Their factory integrates spinning, weaving, dyeing, cutting, embroidery, and packaging under one system, making them a high-efficiency partner for hospitality groups, retailers, and importers.

BCHtowel’s Key Advantages

- 20+ years of towel manufacturing experience

- Export-focused production aligned with EU and U.S. standards

- Vertical integration to ensure stable quality and lead times

- Flexible customization: GSM, size, design, embroidery, packaging

- Competitive pricing for bulk orders

- Consistent quality control with multi-stage inspection

- Support for OEM & private label brands

Businesses looking for a dependable long-term supplier often choose BCHtowel because the company combines factory-level pricing, international-grade quality, and Western-style communication efficiency.

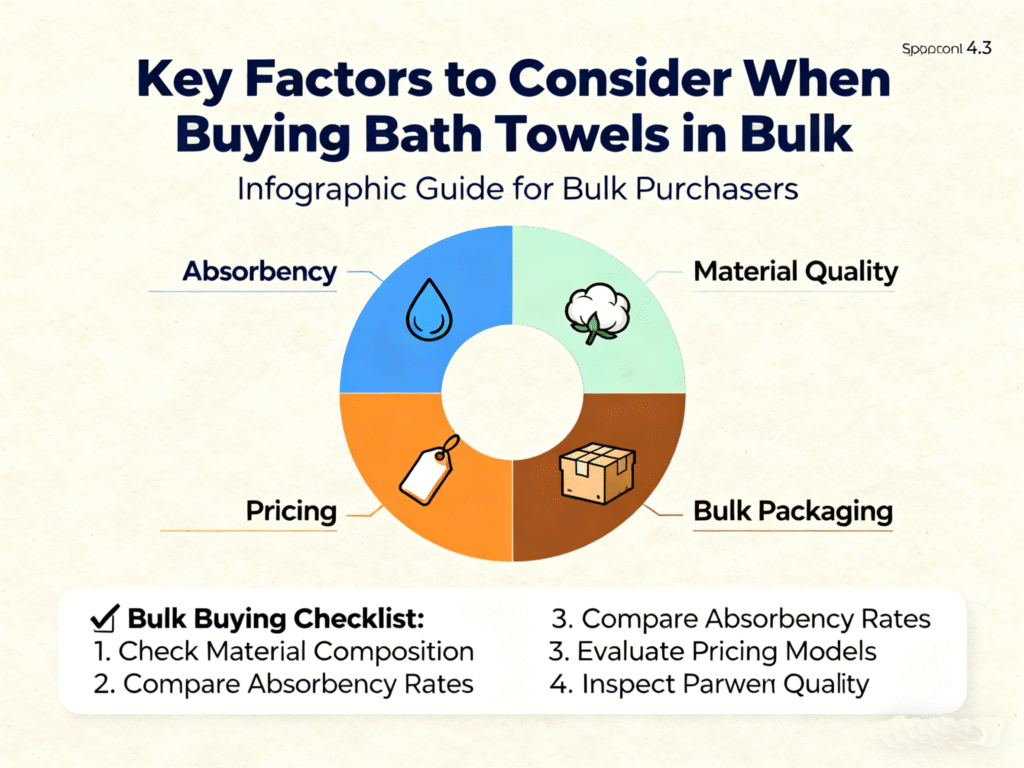

Key Factors to Consider When Buying Bath Towels in Bulk

Bulk towel procurement is a long-term decision that directly affects guest satisfaction, laundry performance, and cost efficiency. Whether you are sourcing for hotels, gyms, spas, retail shelves, or hospitality groups, understanding the technical components of towel quality will prevent issues such as rapid thinning, fraying, discoloration, excessive linting, or poor absorption.

Below is a professional-level breakdown of the essential criteria B2B buyers must evaluate before placing large-volume orders.

Material Selection: Cotton Grades, Fiber Types & Blends

Keywords: “cotton types for bulk towels,” “best cotton for hotel towels,” “zero-twist cotton wholesale”

Towel performance begins with fiber selection. The most common materials used in commercial-grade towels include:

1. Regular Cotton

Affordable, widely available, suitable for budget hotels and gyms.

2. Combed Cotton

Fibers are combed to remove short strands, improving:

- Softness

- Durability

- Absorption consistency

3. Long-Staple Cotton (Premium Grade)

Includes:

- Egyptian cotton

- Turkish cotton

- Xinjiang long-staple cotton

These fibers are longer, stronger, and softer, making them ideal for luxury applications.

4. Ring-Spun Cotton

Fibers are twisted and thinned to create smoother, finer yarns—resulting in:

- Higher durability

- Softer texture

- Superior lifespan under commercial laundering

5. Zero-Twist Cotton

Fibers are stabilized with a water-soluble polymer during production, creating:

- Ultra-soft texture

- Lightweight feel

- Fast drying

Ideal for upscale hotels or spa use.

6. Cotton-Poly Blends

Commonly 85/15 or 90/10 blends. Benefits include:

- Faster drying

- Better longevity in high-volume laundries

- Less shrinkage

Best for: budget hotels, gyms, laundromats

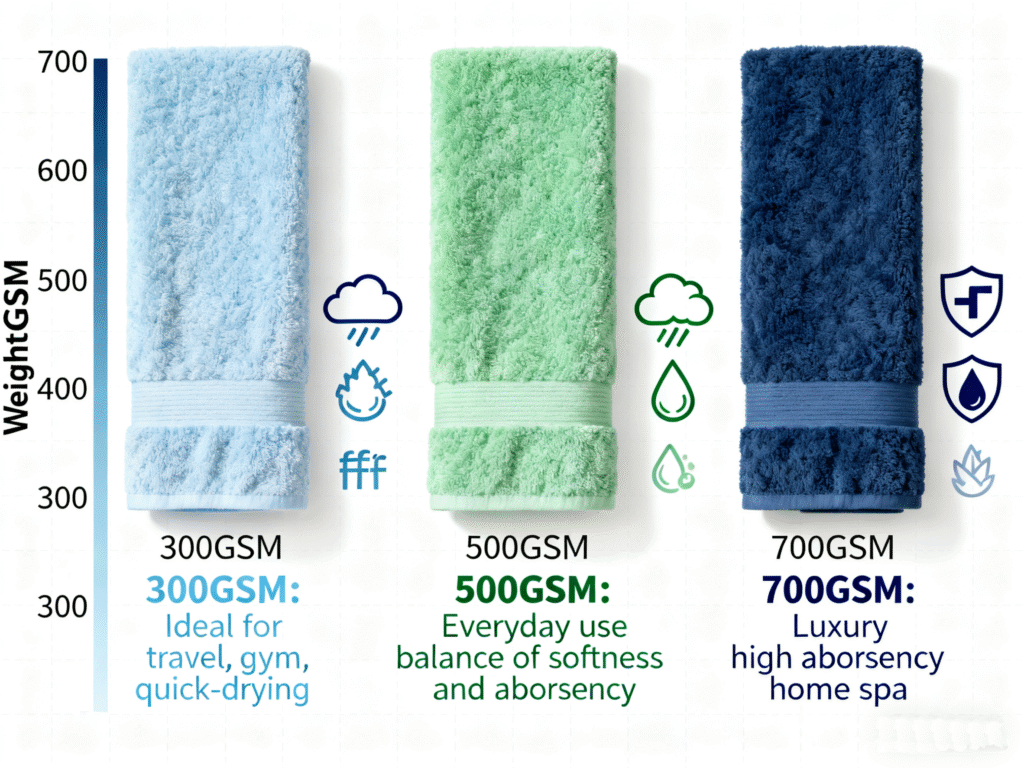

GSM (Grams per Square Meter): Weight Determines Quality & Use Case

GSM affects absorbency, softness, price, and durability. Below is a GSM guide for B2B buyers:

| GSM Range | Characteristics | Suitable For |

|---|---|---|

| 300–400 GSM | Lightweight, fast-drying | Gyms, budget hotels, cleaning services |

| 400–500 GSM | Balanced thickness | Mid-range hotels, spas |

| 500–650 GSM | Plush, highly absorbent | 4-star hotels, luxury gyms |

| 650–900 GSM | Ultra-premium, heavy | 5-star hotels, luxury spas, retail premium lines |

Tip: Higher GSM ≠ better in all cases.

Commercial laundries often prefer 450–550 GSM for optimal lifespan.

Towel Construction: Weave, Loops, and Finishing

Terry Weave

Most common for hotel and bath towels. Provides maximum absorption and durability.

Waffle Weave

Lightweight, textured, and fast-drying. Popular for spas and boutique hotels.

Jacquard Weave

Allows woven patterns or logos. Suitable for branding and retail displays.

Loop Style

- Long loops → softer, more absorbent

- Short loops → stronger, faster-drying

- Double loop → highest durability for industrial laundering

Finishing Techniques

Includes:

- Anti-linting treatment

- Pre-shrinking

- Color fixation treatment (reactive or vat dye)

- Softening finishes for retail-grade hand feel

Absorbency Performance & Lab Testing

A professional supplier should be able to provide:

- Water absorption rate tests

- Colorfastness tests (washing, rubbing, chlorine)

- Tensile strength tests

- Shrinkage tests after laundering cycles

- Linting and pilling measurements

Absorbency is affected by:

- Fiber quality

- Loop density

- GSM and weave

- Dyeing/finishing techniques

Towels with ring-spun yarn + reactive dyeing typically perform best.

Size Standards (US vs. EU) & Recommended Dimensions

Common Bath Towel Sizes

| Towel Type | U.S. Size Standard | European Size Standard |

|---|---|---|

| Washcloth | 13”×13” | 30×30 cm |

| Hand Towel | 16”×30” | 50×90 cm |

| Bath Towel | 27”×52” | 70×140 cm |

| Bath Sheet | 35”×60” | 100×150 cm |

| Spa/Salon Towel | 16”×27” | 40×70 cm |

When buying in bulk, ensure consistency across all cartons.

Colorfastness & Dyeing Method

Reactive Dye

- Vibrant color

- Strong wash fastness

- Ideal for most applications

Vat Dye

- Superior chlorine resistance

- Best for hotels & laundries using strong detergents

Do Not Buy

- Direct dye towels (fade quickly)

Durability Under Commercial Laundering

Hotels and gyms wash towels 200–400 times per year, so durability is critical.

A good commercial-grade towel should withstand:

- High-temperature washing (up to 90°C)

- Chlorine exposure (if applicable)

- Heavy mechanical action

- Commercial tumble drying

Chinese factories like BCHtowel specialize in reinforced hems and double-needle stitching, which significantly extends lifespan.

Packaging Requirements for Retail & Hospitality

Packaging affects shelf appeal, hygiene, and shipping efficiency.

For Retail

- Printed polybags

- Paper band wrapping

- Box sets

- Barcode/label integration

For Hotels

- Bulk compressed packaging

- Vacuum packaging to reduce freight cost

- Moisture-resistant wrapping

MOQ (Minimum Order Quantity) Considerations

Depending on the supplier:

| Supplier Type | Typical MOQ |

|---|---|

| Local wholesaler | 1–2 cartons |

| Online marketplace vendors | 100–300 pieces |

| Chinese factories | 500–5,000 pieces depending on customization |

| Luxury producers (Turkey) | 1,000–3,000 pieces |

Factories typically have higher MOQs because they produce from raw cotton, not stock inventory.

Compliance & Certifications for EU & US Markets

Professional buyers should confirm compliance with:

- OEKO-TEX® Standard 100

- ISO 9001 / ISO 14001

- REACH (Europe)

- CPSIA (U.S.)

- Prop 65 (California)

- AZO-free dyeing

- Colorfastness level 3–4+

Factories like BCHtowel maintain these certifications for all export lines.

Supplier Reliability, Production Capability & Communication Efficiency

Before placing a large order, evaluate:

1. Factory Scale

- Number of looms

- Daily output capacity

- Dyehouse capacity

- Embroidery/packaging lines

2. QC System

- Raw cotton inspection

- Yarn testing

- Pre-production sampling

- In-line QC

- Final AQL inspection

3. Export Experience

Suppliers exporting to Europe/USA understand:

- Compliance rules

- Packaging/labelling requirements

- Shipping documentation

4. Communication

Responsive suppliers reduce risk and speed up decision-making.

BCHtowel, for example, is known for providing:

- Dedicated export account managers

- Professional spec sheets

- Fast sampling

- Clear production timelines

Why Choosing the Right Supplier Matters (Cost Savings Over Time)

Choosing a high-quality supplier reduces hidden costs caused by:

- Towel shrinkage

- Premature thinning

- High replacement rates

- Guest complaints

- Laundry inefficiencies

A reliable manufacturer improves:

- Lifespan

- Consistency

- Brand reputation

- Long-term cost reduction

Cost Analysis & Pricing Breakdown for Bulk Towels

Pricing is one of the most important factors when sourcing bath towels in bulk. However, many buyers focus only on the per-unit cost, overlooking the deeper cost structure that impacts long-term profitability — including material choice, GSM, finishing, packaging, shipping, duty rates, and supplier reliability.

This section breaks down the complete cost model to help B2B buyers understand exactly what they are paying for when purchasing bulk towels.

What Determines the Price of a Bulk Bath Towel?

Wholesale towel pricing is influenced by eight major variables:

1. Cotton Type & Grade

- Regular cotton → lowest cost

- Combed cotton → +5–12%

- Long-staple cotton → +15–35%

- Turkish cotton → high premium

- Zero-twist cotton → +30% due to special spinning process

2. GSM (Weight)

More cotton = higher cost.

Example:

- 400 GSM towel = lower cost, lighter

- 650 GSM towel = significantly higher cost

3. Yarn Structure

- Open-end yarn → cheapest

- Ring-spun yarn → +8–15%

- Zero-twist yarn → +20–30%

4. Weave & Construction

- Basic terry → lowest cost

- Double-loop terry → +10–20%

- Jacquard weave → +20–40%

- Waffle weave → similar to terry but depends on density

5. Dyeing Method

- Direct dye → low cost, not recommended

- Reactive dye → +8–12%

- Vat dye → +15–25% (chlorine-resistant, ideal for hotels)

6. Packaging

- Bulk compressed packaging → cheapest

- Retail packaging (paper band) → +$0.08–$0.15 per towel

- Gift box → +$0.40–$1.50 depending on materials

7. Order Quantity (Economies of Scale)

Higher quantities reduce:

- Cotton waste

- Loom setup time

- Dye-to-batch cost

- QC overhead

8. Supplier Type

- Local wholesalers → highest price

- Trading companies → medium price

- Direct factories → lowest and most stable pricing

Leading Chinese factories like BCHtowel offer the best price-to-quality ratio because they control raw material sourcing, weaving, dyeing, and finishing internally.

Typical Price Ranges for Bulk Bath Towels (China Factory Pricing)

Below is a realistic price reference for buyers in the US and EU markets.

Price Table: Standard Factory-Direct Pricing (Ex-Factory)

| Towel Grade | GSM | Cotton Type | Size (cm) | Typical Price (USD) |

|---|---|---|---|---|

| Economy | 350–400 | Regular cotton | 70×140 | $1.20–$1.60 |

| Mid-range hotel | 400–500 | Combed cotton | 70×140 | $1.90–$2.50 |

| Premium hotel | 500–600 | Ring-spun cotton | 70×140 | $2.80–$3.80 |

| Luxury | 650–700 | Long-staple cotton | 70×140 | $4.20–$6.00 |

| Spa grade | 700–900 | Zero-twist / long-staple | 80×150 | $6.50–$10.00 |

Note: These numbers reflect typical B2B pricing from major Chinese manufacturers, including BCHtowel.

Additional Costs: Shipping, Duties & Logistics

In most sourcing cases, the total landed cost includes:

1. Sea Freight

Shipping from China to:

- West Coast USA → ~14–18 days

- East Coast USA → ~25–35 days

- Europe → ~25–40 days

Approximate freight costs (for towels, high-density cargo):

- LCL: $80–$180 per CBM

- FCL 20’: $900–$1,500

- FCL 40’: $1,200–$2,200

2. Customs Duties

- USA: Most towels fall under HTS 6302, duty ~9–14%

- EU: Usually 8–12% depending on composition

3. Import Fees

- Port fees

- Customs clearance charges

- Local inland transport

4. Storage & Handling

Especially relevant for large-volume buyers storing inventory for multiple months.

Cost Breakdown Example: Hotel Towel Order

Below is a realistic cost simulation for a mid-size hotel chain purchasing from China.

Product Specs

- 500 GSM

- Combed cotton

- White 70×140 cm

- Reactive dyed

- Double-stitched hems

Cost Breakdown

| Cost Component | Amount |

|---|---|

| Factory Price ($2.20 × 10,000 pcs) | $22,000 |

| Sea Freight (40’HQ) | $1,600 |

| Import Duty (10%) | $2,200 |

| Customs + Local Charges | $450 |

| Inland Transport | $380 |

| Total Landed Cost | $26,630 |

| Cost per Towel (Landed) | ≈ $2.66 |

A towel that lands at $2.66 would typically retail in the U.S. for $7–$12, sometimes more in premium stores.

Cost Analysis for Retail Brands (Private Label Projects)

Retailers have added costs beyond towels themselves:

1. Packaging

- Bellyband: +$0.10

- Hang tag: +$0.02–0.05

- Retail polybag: +$0.04–0.10

- Gift box: +$0.50–1.50

2. Labeling

- Custom woven labels

- Care labels complying with US/EU regulations

3. Additional QC

Retail chains often require:

- AQL 1.5–2.5 inspection

- Third-party lab testing (SGS, Intertek)

Extra cost per item: +$0.05–$0.12

4. Barcoding & SKU Segmentation

Adds complexity → requires larger MOQs.

Long-Term Cost Savings: Why Quality Matters More Than Price

Many buyers make the mistake of choosing the cheapest towel, but:

Cheap towels =

✔ shrink faster

✔ lose softness

✔ absorb less over time

✔ require more frequent replacement

✔ generate guest complaints

✔ increase laundry cycles (higher labor cost)

Higher-quality towels =

✔ last longer

✔ maintain absorption

✔ reduce per-use cost

✔ lower long-term replacement rates

✔ enhance brand experience

Choosing a high-quality factory like BCHtowel can reduce your annual replacement cost by 20–40%.

Cost Comparison Table: China vs Other Regions

| Region | Average Price | Quality Consistency | Customization | MOQ | Lead Time | Best For |

|---|---|---|---|---|---|---|

| China | Lowest | High | Best | Medium-high | 15–45 days | Most B2B buyers |

| Turkey | High | Very high | Good | Medium | 20–50 days | Luxury markets |

| India | Low–medium | Medium | Moderate | Medium | 20–45 days | Organic & handloom |

| Pakistan | Low | Medium-low | Limited | Medium | 25–50 days | Budget hotels & cleaning |

China offers the best cost-efficiency for 80% of B2B buyers.

Why Factory-Direct Pricing From BCHtowel Is More Cost-Effective

BCHtowel provides cost advantages that distributors and trading companies cannot match:

1. Vertical Integration

They handle:

- Yarn spinning

- Weaving

- Dyeing

- Cutting

- Embroidery

- Packaging

→ Eliminates multiple middlemen

→ Reduces cost per towel by 12–25%

2. Large-Scale Production

High-speed looms + automated dyeing lines = lower unit cost.

3. Export-Focused Production

They optimize:

- Packing density

- Colorfastness

- Shrinkage rates

- Label compliance

for Western laundries and retail environments.

4. Stable Cotton Sourcing

Long-term contracts ensure consistent pricing even when cotton markets fluctuate.

5. Lower MOQ for Custom Orders

Perfect for:

- Mid-size hotel chains

- Small-to-mid retail brands

- New importers entering the market

BCHtowel is designed to minimize total landed cost while maximizing durability — a key value for long-term B2B relationships.

Summary: The Smartest Cost Strategy for EU & US Buyers

To minimize cost and maximize lifespan:

- Choose 500–550 GSM for most hospitality needs

- Use combed or ring-spun cotton

- Select reactive dye for colored towels

- Order in bulk to reduce freight and unit cost

- Work with a direct factory (not a trading company)

- Prioritize durability, not the cheapest price

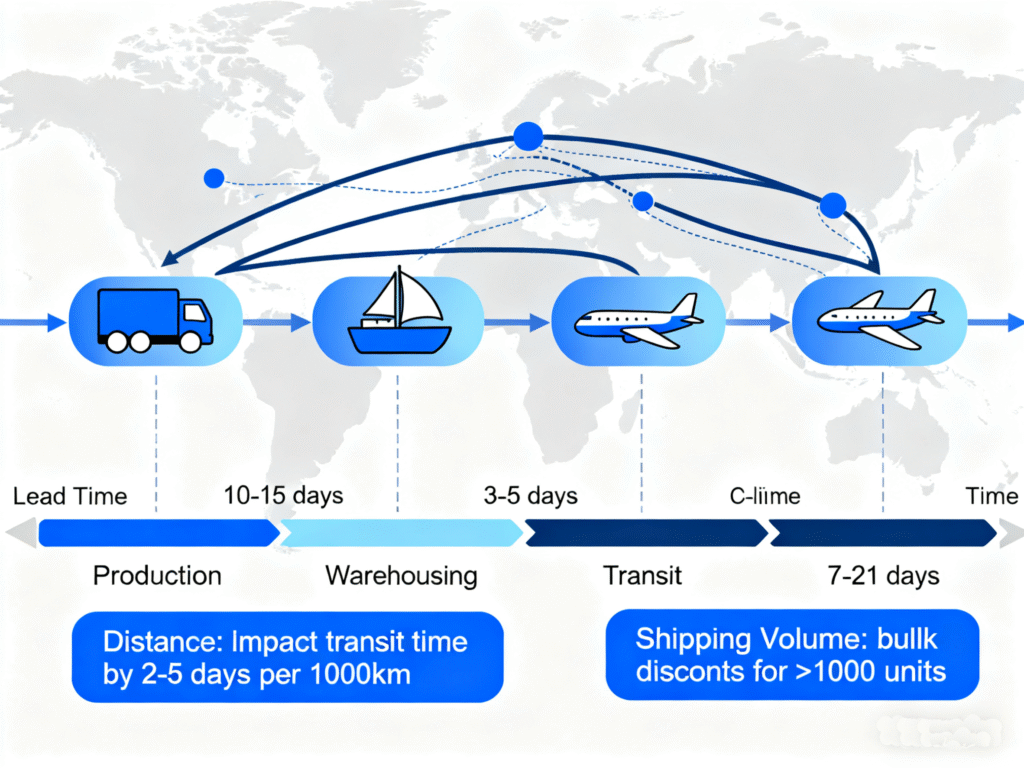

Shipping, Logistics & Lead Times for Bulk Towels

For B2B buyers in Europe and America, sourcing towels is only half the challenge — the other half is efficient shipping and reliable logistics. Delays, customs issues, or freight inefficiencies can significantly impact cost, cash flow, and order fulfillment schedules. Understanding the shipping landscape is crucial for businesses importing towels from Chinese manufacturers like BCHtowel.

Shipping Methods for Bulk Towels

1. Sea Freight (Most Common for Bulk Orders)

- Best for: Orders of 500+ towels

- Containers used: 20’ FCL, 40’ FCL, 40’HQ

- Lead time:

- China → West Coast USA: ~14–18 days

- China → East Coast USA: ~25–35 days

- China → Europe: ~25–40 days

- Pros: Lowest cost per unit for large orders, ideal for hotel chains, gyms, and retail brands

- Cons: Longer lead time; requires coordination with customs

2. Air Freight

- Best for: Smaller, urgent orders (under 1,000 towels)

- Lead time: ~5–10 days

- Pros: Fast, reliable for urgent restocking

- Cons: Much higher cost (5–10× sea freight)

3. Express Shipping (DHL, FedEx, UPS)

- Best for: Samples or very small orders

- Lead time: 2–7 days

- Pros: Fast, door-to-door service

- Cons: Not cost-effective for bulk orders

Freight Cost Calculation

When importing bulk towels, buyers should consider:

1. Chargeable Weight vs Volume

- Towels are light but bulky

- Freight may be charged per CBM (cubic meter) rather than actual weight

2. LCL vs FCL

| Type | Best For | Pros | Cons |

|---|---|---|---|

| LCL (Less than Container Load) | < 10,000 towels | Lower upfront cost | Shared container → longer transit, potential handling delays |

| FCL (Full Container Load) | > 10,000 towels | Safer, faster, lower cost per unit | Requires larger upfront investment |

3. Freight Example

- 40’HQ container → ~25 CBM

- Approx. 15,000–20,000 towels depending on folding & compression

- Estimated sea freight cost → $1,200–$2,200 per container

- Cost per towel → $0.06–$0.12

Factories like BCHtowel pre-optimize packing density to maximize container efficiency.

Customs Clearance & Import Duties

1. USA

- HTS Code for cotton towels: 6302

- Duty: 9–14%

- Required documents:

- Commercial invoice

- Packing list

- Bill of lading / airway bill

- Certificate of origin (if requested)

2. Europe

- CN Code: 6302

- Duty: 8–12%

- Required documents:

- Invoice

- Packing list

- Bill of lading

- CE/REACH compliance for chemical content

3. Tips

- Always confirm HS code classification with your customs broker

- Ensure supplier provides proper documentation

- Include OEKO-TEX, ISO, or REACH certificates if applicable

Transit Time Optimization

Efficient buyers consider:

| Step | Typical Duration | Optimization Tips |

|---|---|---|

| Factory production | 15–30 days (depending on order size) | Confirm production schedule, order early |

| Inland transport (China factory → port) | 1–3 days | Use supplier’s logistics partners |

| Port handling | 2–5 days | Confirm container slot availability |

| Sea transit | 14–40 days | Choose correct port; consolidate multiple shipments if needed |

| Customs clearance | 2–7 days | Work with trusted customs broker |

| Local delivery (port → warehouse) | 2–5 days | Pre-arrange trucking; optimize routes |

Tip: Lead time buffer of 10–15 days helps avoid seasonal delays (e.g., pre-Christmas or Chinese New Year).

Packing Solutions for Bulk Towels

1. Factory Bulk Packaging

- Compressed in polybags → reduces volume → lowers shipping cost

- Neutral or generic packaging, suitable for hotels or laundries

2. Retail-Ready Packaging

- Individual OPP bags, hangtags, paper bands

- Suitable for private-label retail

- Slightly higher shipping volume → slightly higher freight

3. Vacuum Compression

- Reduces bulk by 30–40%

- Ideal for high-volume orders

- Some factories, including BCHtowel, provide vacuum packaging as standard for FCL shipments

Logistics Challenges & Solutions

| Challenge | Solution |

|---|---|

| Peak season port congestion | Plan shipping 2–3 months in advance |

| Damaged towels during transport | Use high-quality cartons, shrink-wrap, corner protectors |

| Delayed customs clearance | Provide complete documentation, work with experienced broker |

| Incorrect HS code classification | Verify codes with supplier and customs |

| Fragile retail packaging | Use inner protection (kraft sheets, bubble wrap) |

B2B buyers often choose factory-managed shipping to reduce risks. BCHtowel, for example, coordinates directly with experienced freight forwarders to deliver FCL or LCL orders with predictable timelines.

Shipping Cost Example for a 40’HQ Container

- Order: 15,000 towels (500 GSM, combed cotton, 70×140 cm)

- Ex-factory cost: $2.20/towel → $33,000

- Sea freight (Shanghai → Rotterdam): $1,600

- Import duty 10%: $3,300

- Port & local delivery: $400

- Total landed cost: $38,300

- Cost per towel: ~$2.55

Observation: Factory-managed logistics, high packing density, and proper container selection reduce per-unit cost by 5–10%.

Tips for European & American B2B Buyers

- Order early: Avoid seasonal shipping spikes and Chinese New Year closures

- Choose full container load (FCL) when possible: Reduces per-unit freight and damage risk

- Verify documentation before shipment: Ensures smooth customs clearance

- Consider long-term shipping contracts: Locks in rates for multiple orders

- Work with experienced suppliers: Manufacturers like BCHtowel coordinate end-to-end logistics, reducing risk and time

Summary

Efficient shipping and logistics are critical for B2B towel buyers. Key takeaways:

- Sea freight is cost-effective for bulk orders; air freight for urgent needs

- Landed cost includes factory price + freight + duty + handling

- Proper packaging reduces volume and protects products

- Working with experienced suppliers like BCHtowel ensures predictable lead times, professional documentation, and reliable delivery to EU and US buyers

Proper planning at the logistics stage can save 10–15% on total cost and prevent shipment delays or quality issues.

Comparing Direct Factories vs Wholesalers vs Marketplaces for Bulk Towels

When sourcing bath towels in bulk, buyers often face three primary options:

- Direct Chinese or regional factories (e.g., BCHtowel)

- Wholesalers and distributors in Europe or the U.S.

- Online marketplaces such as Alibaba, Made-in-China, or Amazon Business

Each option has its own advantages and limitations, affecting cost, quality, customization, lead times, and long-term scalability. Understanding these differences helps businesses make strategic procurement decisions.

Direct Factories

Direct factories manufacture towels from raw cotton to finished product, offering full control over quality and production.

Advantages

- Lowest per-unit cost — no middleman markup

- Customization: GSM, color, logo embroidery, packaging, size

- Consistent quality: vertical integration ensures stable production

- Scalable: can handle 5,000–50,000+ units per order

- Professional export support: documentation, certifications, shipping logistics

Disadvantages

- Higher MOQs for customized products

- Requires import knowledge (duties, shipping)

- Less suitable for very small buyers seeking immediate stock

Best for:

- Hotels, gyms, spas

- Retail chains launching private-label lines

- E-commerce brands scaling operations

Example: BCHtowel is a direct factory that integrates spinning, weaving, dyeing, finishing, embroidery, and packaging. This vertical integration ensures high-quality, factory-direct pricing, and reliable delivery to Europe and the U.S.

Wholesalers & Distributors

Wholesalers purchase towels from factories or trading companies and resell them to buyers. They are common in local EU and U.S. markets.

Advantages

- Lower MOQ requirements than factories

- Quick availability — ideal for urgent restocking

- Simpler import process — handled by the distributor

- Good for standard towels — popular GSMs, white towels, standard sizes

Disadvantages

- Higher cost due to markup

- Limited customization — rarely offer private-label services

- Variable quality — multiple sources may reduce consistency

- Not suitable for scaling private-label brands

Best for:

- Small hotels or gyms with small orders

- Retailers needing fast delivery of common towel SKUs

Online Marketplaces

Online platforms connect buyers with factories, trading companies, and wholesalers worldwide. They are increasingly popular for startups and small-scale importers.

Advantages

- Wide selection — thousands of suppliers and product variations

- Low MOQs for testing — ideal for sampling and pilot programs

- Price transparency — easy to compare unit prices

- Convenience — quotes, communication, and documentation online

Disadvantages

- Supplier reliability varies — risk of fake listings or trading intermediaries

- Quality inconsistency — photos may not reflect real products

- Limited B2B consultation — fewer professional recommendations for GSM, weave, or compliance

- Hidden costs — shipping, duty, inspection may be underestimated

Best for:

- Startups exploring private-label towels

- Buyers testing multiple suppliers before committing to large-scale orders

- Sampling new towel designs

Comparative Table: Direct Factories vs Wholesalers vs Marketplaces

| Factor | Direct Factory (e.g., BCHtowel) | Wholesalers/Distributors | Online Marketplaces |

|---|---|---|---|

| Cost per unit | Lowest | Medium-high | Medium |

| Customization | Excellent | Limited | Moderate |

| MOQ | Medium-high | Low | Low |

| Quality consistency | High | Medium | Variable |

| Lead time | 15–45 days | 3–14 days | 7–30 days |

| Documentation & Compliance | Full export support | Medium | Limited / Buyer-managed |

| Scalability | Very high | Medium | Limited |

| Risk | Low with experienced factory | Medium | Higher (unknown suppliers) |

| Best for | Hotels, gyms, private-label brands, large orders | Small-mid buyers, urgent needs | Sampling, startups, exploratory orders |

Observation:

For long-term business growth, direct factories like BCHtowel provide the best balance of cost, quality, customization, and scalability. Wholesalers are convenient for small orders, while online marketplaces are ideal for testing and sampling.

Strategic Recommendations for EU & US Buyers

- Large-volume or private-label orders: Always source from a direct factory.

- Small or emergency orders: Use local wholesalers for speed.

- Testing new products: Use online marketplaces to validate quality and market acceptance.

- Supplier verification: Always request certifications (OEKO-TEX, ISO, REACH) and production samples before bulk purchasing.

- Logistics planning: Factor shipping, duty, and lead times into total landed cost. Direct factories often offer the best support for this.

Why BCHtowel Excels Over Wholesalers and Marketplaces

BCHtowel is a professional, export-focused Chinese towel manufacturer that addresses all major sourcing pain points for EU and US buyers:

- Cost efficiency: Eliminates distributor markup and middleman fees

- Customization: OEM/ODM services, private-label solutions, color matching, embroidery, packaging

- Quality consistency: Vertical integration ensures uniform GSM, soft texture, and colorfastness

- Scalable production: Capable of 50,000+ towels per month

- Professional export support: Shipping, documentation, customs assistance

By choosing BCHtowel, B2B buyers gain a reliable long-term partner capable of supporting growth, private-label retail expansion, and large-scale hospitality procurement.

How to Evaluate a Factory Before Placing a Bulk Order

Selecting the right factory is critical for long-term success in bulk towel sourcing. Even with low prices, a supplier that cannot maintain quality, compliance, or delivery reliability can result in higher costs, product recalls, and damaged reputation.

This section provides a step-by-step guide for EU and US buyers to evaluate towel factories like BCHtowel before committing to bulk orders.

Verify Factory Credentials & Certifications

Start by requesting:

- Business license and export license

- ISO 9001 / ISO 14001 certification

- OEKO-TEX Standard 100 certificate

- REACH compliance (Europe)

- CPSIA compliance (U.S.)

- AZO-free or eco-safe dye certificates

Tip: Genuine factories will provide up-to-date, verifiable certificates and allow buyers to cross-check with certification bodies.

Inspect Production Capabilities

Assess whether the factory can meet your order volume:

- Number of looms and production lines

- Dyehouse capacity and technology

- Cutting, embroidery, and finishing lines

- Daily output per SKU

- Flexibility for custom sizes, GSM, or patterns

Red flag: Factories with outdated machines or low production speed may struggle to fulfill large orders on time.

Quality Control & Testing Procedures

A strong QC system includes:

- Raw material inspection — cotton quality, fiber length, and cleanliness

- In-line inspection — weaving, dyeing, stitching quality

- Pre-shipment inspection — AQL sampling, GSM, loop density, colorfastness

- Third-party lab testing — optional for private-label or luxury brands

Factories like BCHtowel often provide multi-stage inspections and full QC reports for every order.

Sample Orders & Pilot Runs

Before committing to bulk orders:

- Request a production sample matching the final specification

- Check for softness, color consistency, GSM, absorbency, shrinkage, and hem durability

- Launder samples under commercial conditions to simulate real-world usage

- Adjust any specifications based on results before full production

Factory Site Visit or Virtual Audit

- On-site visit: Confirm production capacity, workforce professionalism, hygiene, safety, and workflow efficiency

- Virtual audit: Live video walk-through of production lines, dyehouses, and packing areas

- Review storage facilities for raw materials and finished goods

Tip: Experienced suppliers like BCHtowel offer virtual audits for overseas buyers unable to travel.

Verify Communication Efficiency & Responsiveness

Reliable communication reduces misunderstandings and production errors:

- Dedicated account manager for your order

- Clear production timelines and updates

- Prompt response to technical questions

- Professional handling of shipping and documentation

Observation: Factories with slow or unclear communication often lead to costly delays.

Review Customer References & Case Studies

- Request references from other EU or US clients

- Review past orders for hotels, gyms, spas, or retail chains

- Ask about delivery reliability, quality consistency, and after-sales support

Positive references provide confidence in long-term partnership viability.

Check Export Experience & Logistics Support

A professional factory should manage:

- Shipping documentation (invoice, packing list, bill of lading)

- Export compliance for EU and U.S. markets

- Logistics coordination for FCL or LCL containers

- Customs clearance support and guidance

Factories like BCHtowel integrate logistics expertise, reducing risk of delays or penalties.

Evaluate Cost Transparency & Payment Terms

- Ask for detailed cost breakdowns: unit price, packaging, shipping, duty

- Confirm MOQ and pricing tiers for larger volumes

- Negotiate payment terms (T/T, L/C, or escrow for first-time orders)

- Avoid hidden charges that trading companies may impose

Tip: Transparent factories simplify budgeting and reduce risk of unexpected costs.

Make a Decision Using a Supplier Scorecard

Create a scorecard to compare multiple factories:

| Criteria | Weight | Factory A | Factory B | Factory C |

|---|---|---|---|---|

| Price | 20% | 8/10 | 7/10 | 6/10 |

| Quality & Compliance | 25% | 9/10 | 8/10 | 7/10 |

| Customization | 15% | 10/10 | 6/10 | 5/10 |

| Production Capacity | 15% | 9/10 | 8/10 | 6/10 |

| Lead Time & Logistics | 15% | 9/10 | 7/10 | 5/10 |

| Communication & Responsiveness | 10% | 10/10 | 8/10 | 6/10 |

| Total Score | 100% | 9.0 | 7.5 | 5.9 |

Factories with scores above 8.5 are generally reliable for long-term partnerships.

Why BCHtowel Excels in Supplier Evaluation

BCHtowel stands out because it consistently scores high across all evaluation criteria:

- Quality & compliance: OEKO-TEX, ISO, REACH, CPSIA certified

- Production capacity: 50,000+ towels per month

- Customization: Full OEM/ODM options, logo embroidery, private-label packaging

- Logistics: Factory-managed shipping, customs support, FCL/LCL expertise

- Communication: Dedicated account managers, rapid response, technical guidance

- Customer references: Trusted by hotels, gyms, spas, and retail brands in Europe & America

For B2B buyers, BCHtowel reduces risk and ensures a reliable, cost-effective, and scalable supply chain.

Tips for Successful Long-Term B2B Bulk Towel Procurement

Sourcing towels in bulk is not just about a single transaction; it is about building a long-term supply chain that guarantees consistent quality, cost efficiency, and reliable delivery. For hotels, gyms, spas, retailers, and private-label brands in Europe and America, establishing the right procurement strategy is critical to maximize ROI and maintain brand reputation.

Develop a Clear Product Specification Sheet

A detailed product spec sheet ensures both the buyer and factory are aligned on expectations:

- Material type (combed cotton, ring-spun, zero-twist)

- GSM range (weight per square meter)

- Size dimensions (bath towel, hand towel, bath sheet)

- Weave type (terry, waffle, jacquard)

- Color and dyeing method (reactive, vat, eco-safe)

- Finishing (pre-shrinking, anti-lint, softening)

- Logo placement and embroidery

- Packaging type (retail-ready, bulk, vacuum)

Tip: Include tolerance ranges for GSM, color, and size to avoid production disputes.

Establish MOQ and Volume Planning

- Determine initial order volume based on inventory needs, budget, and storage capacity

- Negotiate pricing tiers for larger orders to benefit from economies of scale

- Plan reorder intervals to avoid stockouts or overstocking

Observation: Factories like BCHtowel often offer flexible MOQ options for repeat buyers and private-label brands.

Build Long-Term Supplier Relationships

Long-term partnerships reduce risk and improve operational efficiency:

- Share forecasted order volumes with suppliers

- Commit to consistent quality and repeat orders

- Maintain open communication channels

- Negotiate better pricing and faster lead times for loyal customers

Benefit: Long-term partnerships often include priority production slots, custom packaging, and early access to new products.

Monitor Quality Regularly

Even with reliable factories:

- Conduct periodic sample checks before full shipment

- Test absorbency, shrinkage, softness, and colorfastness

- Track wash cycles in commercial laundering to ensure durability

- Implement feedback loop with supplier to address any issues

Tip: Factory-managed QC reports and third-party inspections enhance accountability.

Optimize Lead Times & Inventory Management

- Plan orders 3–6 months in advance for seasonal peaks

- Factor shipping and customs clearance times

- Use safety stock levels to mitigate supply disruptions

- Collaborate with the factory for staggered production schedules

Observation: Factories like BCHtowel provide transparent production timelines and shipping updates, reducing uncertainty for B2B buyers.

Diversify Product Portfolio & Explore Private-Label Opportunities

- Offer multiple GSM and weave options to cater to different market segments

- Introduce luxury towels or spa-grade towels for higher margins

- Consider private-label packaging for retail or hospitality branding

Benefit: Diversification reduces dependency on a single product line and enhances market competitiveness.

Leverage Technology for Order Tracking & Analytics

- Use ERP or inventory management software to track orders and shipments

- Analyze cost per unit, lead times, and supplier performance

- Forecast demand using historical sales data to prevent stockouts

Observation: Digital tools streamline communication, reduce errors, and improve procurement efficiency.

Negotiate Transparent Pricing & Payment Terms

- Request detailed pricing breakdown (unit cost, packaging, shipping, duty)

- Negotiate volume discounts for recurring orders

- Consider payment terms: T/T 30% deposit, 70% balance; L/C; or escrow for first-time orders

Benefit: Clear payment terms protect both parties and facilitate long-term cooperation.

Plan for Compliance & Certification Updates

- Ensure all towels meet OEKO-TEX, REACH, CPSIA standards for target markets

- Keep records of certificates and lab tests

- Request periodic updates from the factory for any regulatory changes

Benefit: Compliance prevents customs delays, fines, or recalls.

Why BCHtowel is Ideal for Long-Term B2B Procurement

BCHtowel is designed for sustainable, long-term partnerships:

- Factory-direct pricing: reduces per-unit cost for recurring orders

- High customization capability: private-label, embroidery, multiple GSM and weave options

- Consistent quality: strict QC at every production stage

- Reliable logistics: managed shipping, customs support, FCL/LCL expertise

- Dedicated account managers: maintain open communication, track orders, and provide technical guidance

By partnering with BCHtowel, European and American buyers ensure cost efficiency, reliable supply, and scalable procurement, making it easier to maintain consistent towel quality across hotels, spas, gyms, and retail outlets.

Conclusion & Key Takeaways for Bulk Towel Buyers

Successfully sourcing bulk bath towels for the European and American markets requires more than finding a low price. It demands a strategic approach encompassing factory selection, cost analysis, quality control, logistics, and long-term supplier management.

Throughout this guide, we have explored every step a B2B buyer must consider — from evaluating factories, understanding pricing structures, navigating shipping logistics, to building long-term partnerships with trusted suppliers like BCHtowel.

Key Takeaways

- Choose the right supplier type:

- Direct factories like BCHtowel provide the best combination of cost, quality, and scalability.

- Wholesalers and marketplaces serve specific purposes such as urgent restocking or sampling.

- Focus on quality, not just price:

- High-quality towels last longer, reduce replacement frequency, and enhance customer experience.

- Consider factors like GSM, cotton type, weave, and finishing.

- Analyze full cost structure:

- Include ex-factory price, shipping, import duties, packaging, and local handling.

- Use tables, simulations, and landed cost calculations to avoid hidden costs.

- Optimize shipping and logistics:

- Sea freight is cost-effective for large orders; air freight suits urgent or small quantities.

- Proper packing, container choice, and customs documentation prevent delays.

- Evaluate factories thoroughly:

- Verify credentials, certifications, QC processes, production capacity, and customer references.

- Conduct sample orders and virtual or on-site audits before committing to large orders.

- Develop long-term relationships:

- Forecast volume, maintain open communication, and collaborate on quality improvement.

- Factories like BCHtowel provide dedicated account managers to support growth.

- Leverage technology:

- Use ERP systems, inventory management, and analytics to track performance, costs, and reorder schedules.

- Ensure regulatory compliance:

- Confirm OEKO-TEX, REACH, and other certifications for EU and US markets.

- Maintain updated records and request periodic factory verification.

Why BCHtowel is a Preferred Choice for EU & US B2B Buyers

BCHtowel is a professional, export-focused towel manufacturer in China, trusted by hotels, gyms, spas, and private-label brands in Europe and America. Its competitive advantages include:

- Factory-direct pricing for cost efficiency

- Vertical integration ensuring consistent quality from yarn spinning to packaging

- Customization capability for OEM/ODM, logos, and private-label options

- Reliable logistics and export experience

- Dedicated account management for seamless communication and support

Partnering with BCHtowel allows B2B buyers to reduce risk, lower costs, maintain high product quality, and scale their operations efficiently.

Final Recommendations

- Start with a detailed specification sheet and sample orders

- Use cost analysis and shipping optimization to determine landed costs

- Conduct factory evaluations before full production

- Plan long-term procurement strategies and maintain ongoing quality monitoring

- Choose a trusted factory partner like BCHtowel for reliable, scalable, and high-quality towel supply

By following these strategies, European and American B2B buyers can ensure profitable, efficient, and sustainable bulk towel sourcing.

FAQ

Reputable home goods retailers, hotel-linen suppliers, and specialty textile brands offer the best-quality towels. Look for vendors known for premium cotton, high GSM, and consistent manufacturing standards.

Towels typically go on sale during January white sales, mid-year clearance events (June–July), and major shopping periods such as Black Friday.

The best value towels are usually 100% combed cotton or ring-spun cotton with a GSM of 500–650. They provide strong absorbency, durability, and softness without premium-price inflation.

Five-star hotels commonly use long-staple cotton towels—often Turkish cotton or Egyptian cotton—with a GSM of 600–800. These towels are plush, highly absorbent, and designed for luxury use.

Under regular use, bath towels should be replaced every 1–2 years, or sooner if they lose absorbency, show fraying, or develop persistent odors.